Team of Solution Providers

Broad expertise IN-HOUSE, spanning many capabilities and specialties

From initial design through final testing and approval, our ODA team will speed the certification process and issue your STC to move your product to market or return your aircraft to service. We leverage the engineering experience gained from our innovative auxiliary fuel system products and VVIP interior designs to integrate any system into existing aircraft. Our technical publications team creates clear succinct operational, maintenance and continued airworthiness manuals.

Turn-key engineering and certification capability

Accelerated timelines versus direct FAA submission

Wide range of engineering and certification experts

Full spectrum project management

Optimize and align STC structure with product market

Life cycle support for STCs

Foreign validation coordination

Minimizing Client Downtime Through ODA Status

Certification & ODA Services

Long history of stc excellence

Based on our track record of FAA compliance with challenging designs, the ALOFT Organization Designation Authorization (ODA) has earned FAA delegation to approve a broad array of flight-worthy products.

We support all types of aircraft

We support all types of systems

We are a long-standing and high performing oda

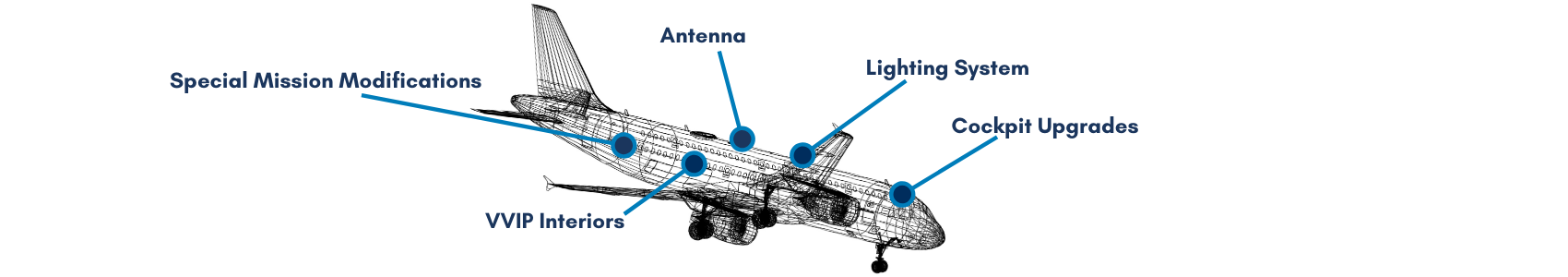

Complete Engineering Design, Systems Integration, Analysis & Final Certification Approval

Engineering Services

Bringing unique thinking and solutions to aviation challenges

Electrical Engineering

Innovation drives our team. Our unique capabilities enable us to integrate a broad spectrum of advanced technologies with aircraft systems for both civil and military applications. We offer our customers a comprehensive turn-key solution that includes conceptual designs, detailed wiring diagrams, and substantiation documentation for both testing and analysis. We specialize in VIP interior completions, 3rd party modifications and special missions system design.

- 14 CFR Parts 23, 25, 27 & 29 Aircraft

- Avionics integration Modifications (ADS-B Out, FAN, etc.)

- ARP4761 System Safety Analysis support

- DO-160 Environmental support

- DO-178 Software support

- System integration Modifications (SATCOM, Auxiliary Fuel, etc.)

- Printed Circuit Board designs

- LRU Hardware designs

- R&D Engineering Laboratory

- Transmit Portable Electronic Device (T-PED) Testing support

- Wiring Diagrams meet ATA 100 standard-all associated Ch.91 data (Hookup list, Wire list, etc.)

- Wire Harness Assembly designs

- EWIS SSA-all supporting analysis/test plans per 25.1701.

- Full VIP Interior Completion data package – Green or Refurbishment

- Diagrams, Analysis, Test Plans/Reports, etc.

- R&D Engineering Laboratory

- Transmit Portable Electronic Device (T-PED) Testing support

MECHANICAL ENGINEERING

For nearly 40 years, we have been continuously designing, manufacturing, installing and certifying auxiliary fuel system (AFS) solutions for a variety of aircraft. In addition to developing racks, trays and other installation solutions for electronic LRUs, our highly-trained and qualified team of experienced engineers can solve for the most challenging technical requirements presented by any VIP aircraft interior installation.

- Fuel System Design

- Seal, Valve, and Manifold Design

- Pressure Relief Design

- Noise and Thermal Insulation Design

- Electrical Bonding and Wire Routing

- Motive Force Design

- VIP Completions Design and In-Flight Entertainment

- Periphery equipment (lights and speakers) in interior liner

- CMS equipment – touch panel, light control, USB ports

- Plumbing Design

- Monuments, Divans and Galley Equipment Design

- Water/Waste

- Environmental Control System

- Install of OML Equipment

- Large External Radomes, Antenna and Adapter Plates

- Antenna Power Supply & Satellite

- Smoke Detection Fire Suppression System Design

- ARINC 600 and 404 rack, tray, hold down and cooling fan/plenum design

- Environmental Control System Analysis

- Monte Carlo Analysis

- Human Factors Analysis

- Rapid Decompression Analysis and Blowout Panel Design

- REACH & RoHS Compliant Designs

- Fluid Flow, Thermal and Ventilation Simulation and Analysis

- ETOPS Analysis

- Egress Analysis

- 3-D printing Fused Deposition Modeling (FDM)

- Testing Capabilities:

- Engineering Dry Lab

- Auxiliary Fuel System Test Rig

- Full System Testing

- Adaptable Simulating for Various A/C Platforms

STRUCTURES ENGINEERING

From part detail to system integration to airframe level evaluations, our in-house team of structural engineers and analysts have the knowledge and capabilities to tackle the toughest design challenges. We support a wide variety of design solutions and produce the necessary structural substantiation reports that are required for certification efforts.

- Outer Mold Line Modifications – Antenna Radomes, Winglets and Finlets

- Dynamic Analysis

- Aerodynamic Loads Analysis

- Birdstrike Analysis

- Flutter Analysis

- Vibration and Buffeting Analysis

- Primary Structure Modifications – Fairings, Cargo Compartment Modifications

- 5 ft/s Fuselage Evaluations (14 CFR 25.721 compliance)

- Windmilling Analysis

- Rotorburst Shielding Design

- Substantiation of Structural Airframe Modifications & Repairs (MRO)

- Static Strength

- Fatigue / Damage Tolerance Analysis

- NASGRO v9.2

- Finite Element Analysis (FEMAPv12 / NX Nastran)

- Linear Static

- Modal / Frequency Response

- Buckling

- FEM Validation (Testing / Classical Methods)

- Custom Honeycomb Panel Material Testing (14 CFR 25/27/29.613 compliance)

- Substantiation of Structural Airframe Modifications & Repairs (MRO)

- Real-time MRB Support

- Weight and Balance Change Assessments

System Safety Engineering

From In-cabin Entertainment Systems to Auxiliary Fuel Systems (AFS), we ensure that our System Safety Assessments (SSA) successfully meets our customer’s certification needs. In order to demonstrate that all safety measures are met, we use a systematic comprehensive evaluation of the overall system integration. Our evaluation ensures that the system performs its intended functions and that the overall safety, both physical and functional failures, meet the requirements of relevant FARs and JARs. In addition, we check for probability of occurrence and hazard severity while ensuring the system’s effects on airplane level hazards are well understood.

- Boeing Classic, Next-Generation and MAX 737-7 Auxiliary Fuel Systems

- Commercial Aircraft Corporation of China (COMAC) ARJ21-700 Auxiliary Fuel System

- Various VIP Aircraft Interior Installations

- Large aircraft Cockpit Management Systems

- Functional Hazard Analysis

- System and SubSystem Hazard Analysis

- Failure Modes and Effects Analysis

- Reliability Analysis

- Fault Tree Modeling and Analysis

- Common Mode and Common Cause Analysis

- System Safety Analysis

- Human Factors Assessment

- Experience dealing with foreign authorities

Engineering Design and Drafting

The Design and Drafting team provides detailed pictorial renderings, material strength data models, dimensional models and drawings for analysis as well as fabrication and installations of a wide range of products.

- Custom aircraft interior installations

- Auxiliary fuel tank systems

- Electronic racks and trays

- In Flight Connectivity and Entertainment systems

- 2D and 3D CAD Design Software to ASME standards

- Digital Model/Drawing Data to suppliers for Automated CNC

- Manufacturing and CMM Inspections

- Prototype and flight-approved 3D printed Parts on our FORTUS printer

- AutoCAD and AutoCAD Electrical (2D)

- Inventor, Solid Works & CITIA V5 (3D models and Drawings)

- Image files such BMP, JPEG, PNG or TIFF

- Prototype parts printed in ABS plastic.

- Flight approved parts printed in ULTEM 9085

Industry Leading Technical Library

Technical Publications Services

Accurate. Detailed. User-Friendly.

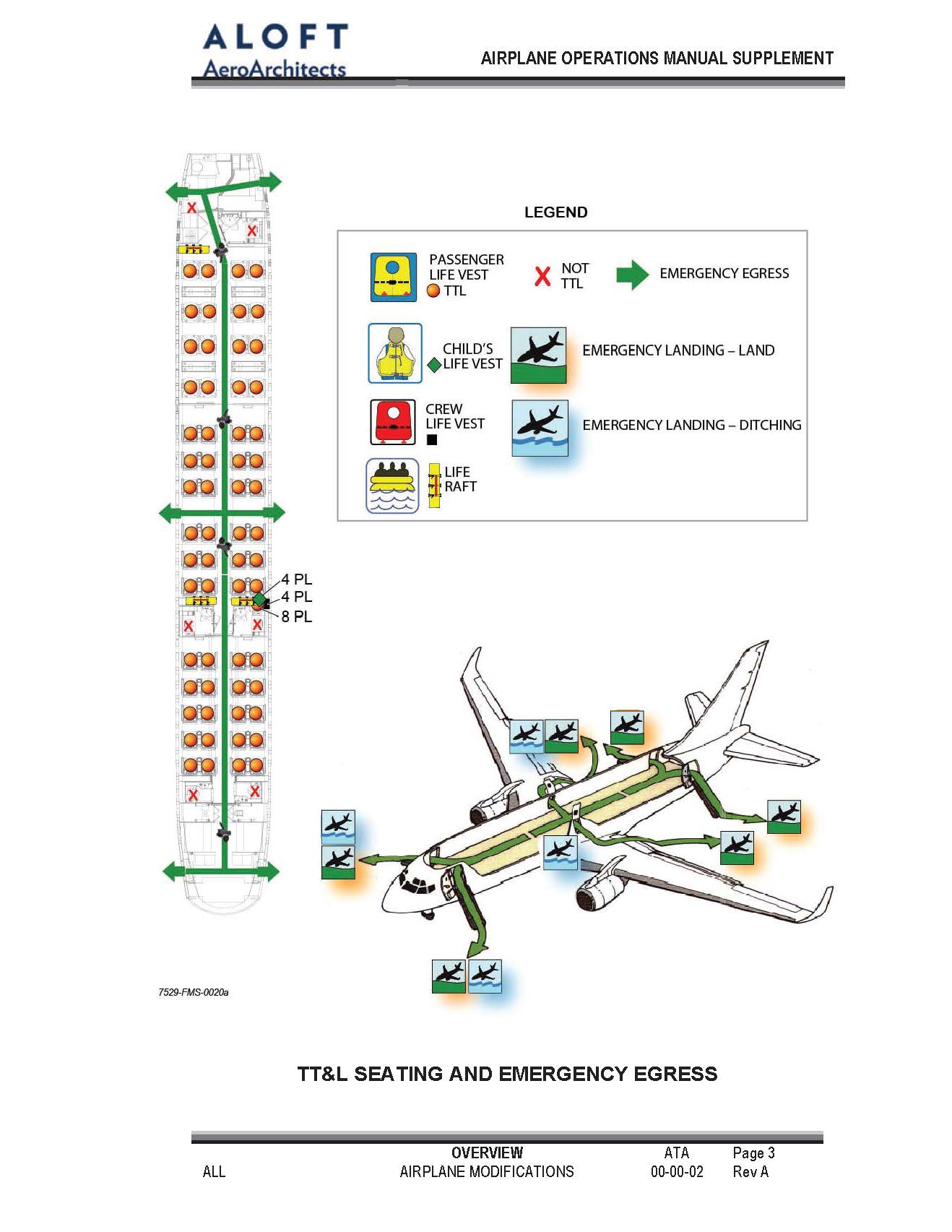

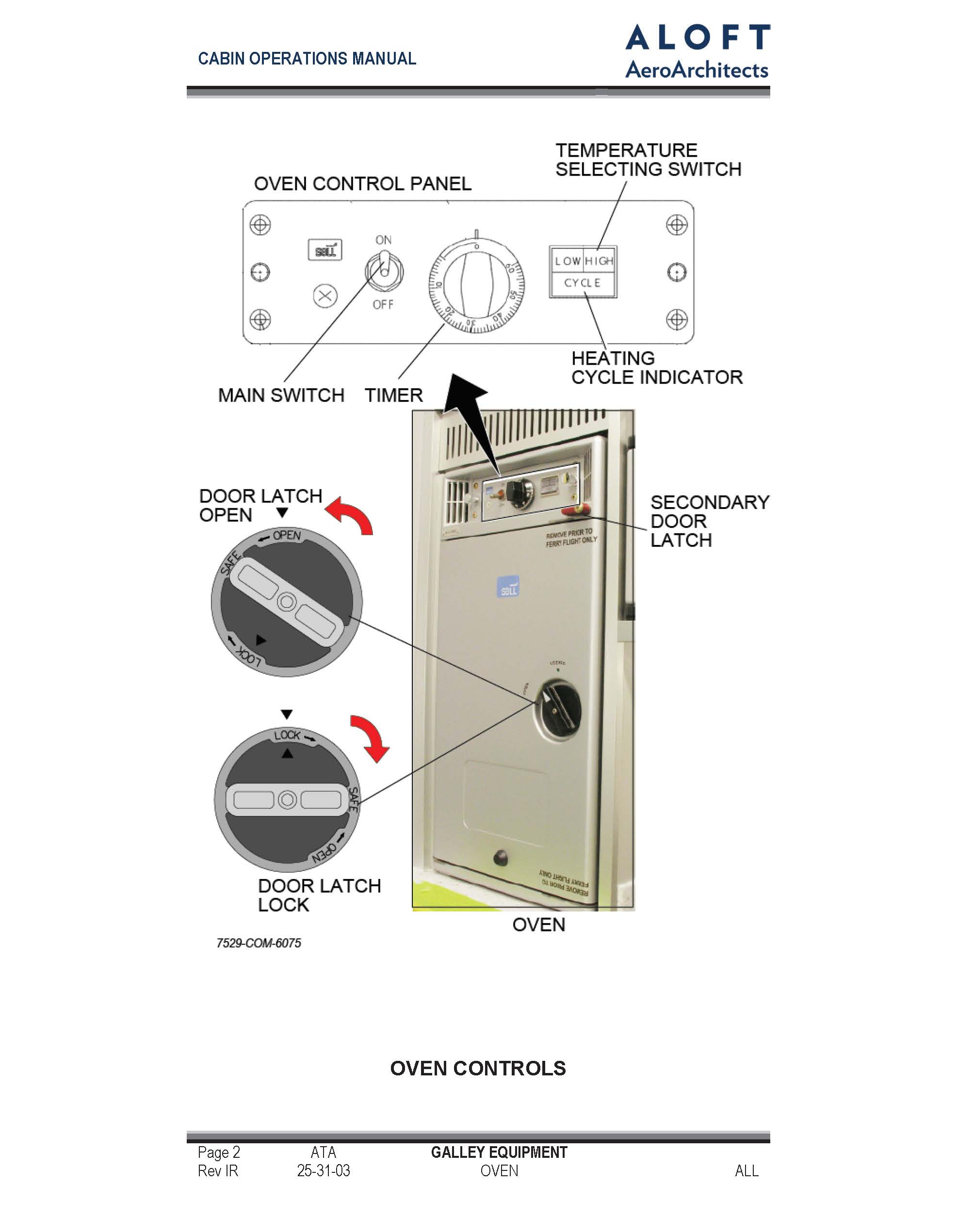

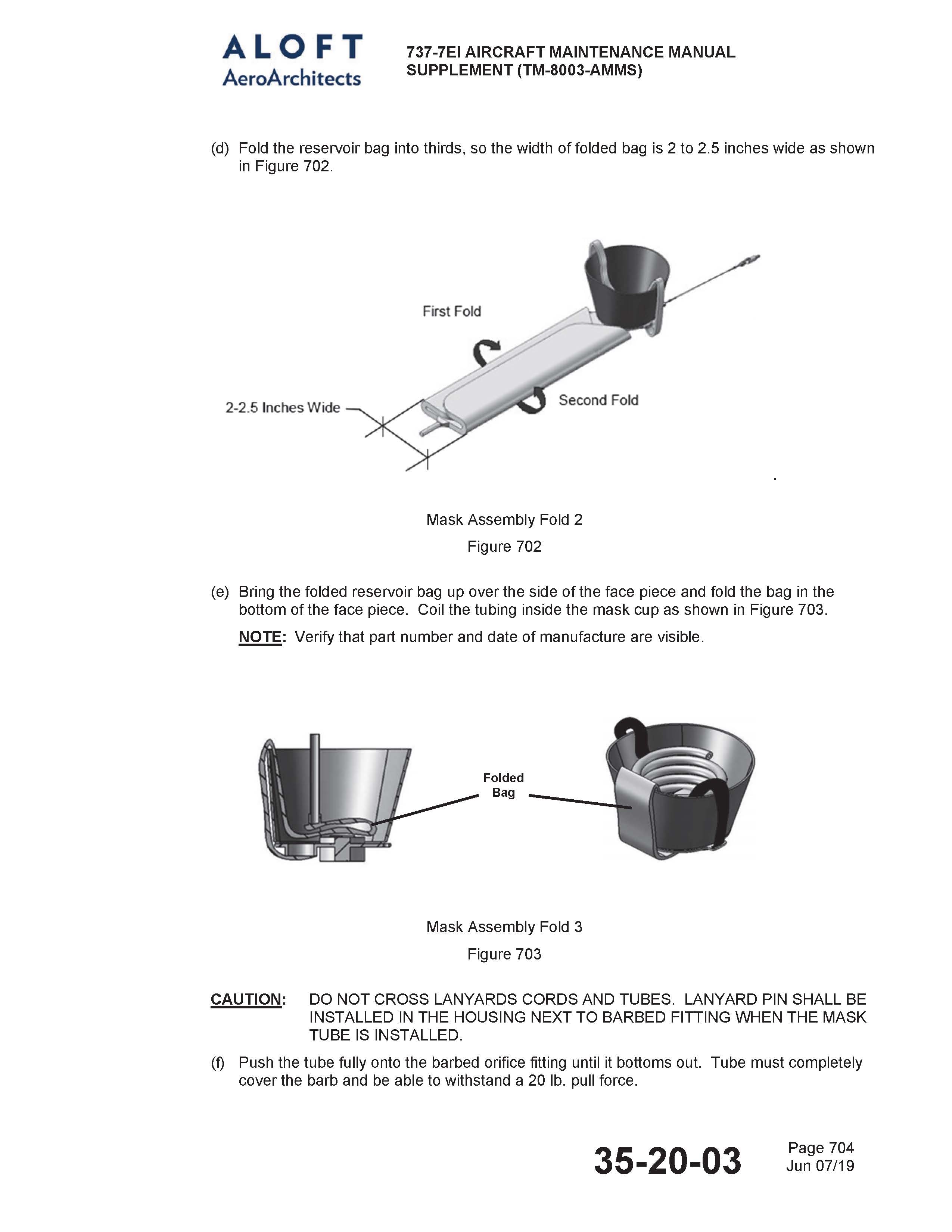

Our full-service in-house team offers a wide range of technical publications services including the creation of electronic publications of Airplane Flight Manual Supplements and Instructions for Continued Airworthiness (ICAW). Our team has the skills and expertise to create fully customizable publication packages. In addition, we can also provide a detailed review of existing aircraft technical documents and create new, easily manageable and well-organized manual sets.

- Aircraft Maintenance Manual Supplements (AMMS)

- Airplane and Rotorcraft Flight Manual Supplements (FMS)

- Component Maintenance Manuals (CMM)

- Electrical Wiring Interconnection System Instructions for Continued Airworthiness (EWIS ICA)

- Engineering Orders (E/O)

- Fault Isolation Manual Supplements (FIM)

- Flight Attendant Manual Supplements (FAMS)

- Illustrated Parts Catalog Supplements (IPCS)

- Instructions for Continued Airworthiness (ICAW)

- Maintenance Planning Data Supplements (MPDS)

- MSG-3 Analysis

- Passenger Briefing Cards (PBC)

- Part Information Letters (PIL)

- Service Bulletins (SB)

- Service Letters (SL)

- Temporary Revisions (TR)

- Wiring Diagram Manual Supplements (WDMS)

- Flight Crew Operations Manual (FCOM)

- Cabin Crew Operations Manual (CCOM)

- EWIS ICA

Creating Easily Adaptable STC Solutions

STC Catalog

Supplemental Type Certificates FOR PURCHASE

Air Ionization STC

ALOFT is offering the only stand-alone AML-STC for installation of the Aviation Clean Air (ACA) proactive Air and Surface purification components. The components and installation methodology are designed (in the physical size, capacity and design) to fit into any aircraft which will immediately improve interior air quality and kill pathogens where they sit on all surfaces wherever the conditioned air reaches.

NextGen ADS-B Out STC

ALOFT installs the supplemental type certification (STC) process for ADS-B Out compliance solution. Our FAA ODA capabilities allows us to complete the complex design, installation and STC certification process for ADS-B compliance within the tight schedule of a routine maintenance inspection.